PRODUCTS

Phytase

Category:

keyword:

Phytase

Product details

Product Overview

Aocter Group Aobo phytase is a product produced by modern bioengineering technology and optimized high yield, through liquid submerged fermentation technology and unique post-treatment process. This product has very high specific activity and cost performance; stable in feed Excellent performance; comprehensive dosage forms.

Excellent enzyme source

1. 3-Phytase has better stability in feed.

2. Wider pH range and temperature range.

Product Features

♦ The enzyme activity measurement adopts the new national standard, which has higher enzyme activity and better cost performance.

To implement the standard GB 7300.402-2020, the amount of enzyme required to release 1µmol inorganic phosphorus from a sodium phytate solution with a concentration of 5.0mmol/L per minute at 37°C and a pH value of 5.5 is 1 phytic acid Enzyme activity unit, represented by U.

♦ Advanced processing technology, micro-granule dosage form, excellent fluidity, more conducive to uniform mixing.

|

Phytase (take 10,000 enzyme activities as an example) |

|

|

Test weight (kg/L) |

1.27 |

|

Average particles per gram of product |

about 70000 |

|

Total number of particles when adding 200g |

About 14 million |

|

Enzyme activity (U/g) |

≥10000 |

|

Average particle size (mm) |

0.24 |

|

<0.10mm |

0% |

|

0.10-0.15mm |

2% |

|

0.15-0.25mm |

49% |

|

0.25-0.425mm |

48% |

|

0.425-0.60mm |

1% |

|

0.60-0.85mm |

0% |

|

0.85-1.00mm |

0% |

|

>1mm |

0% |

|

dust, mg |

0 |

|

fluidity |

Excellent |

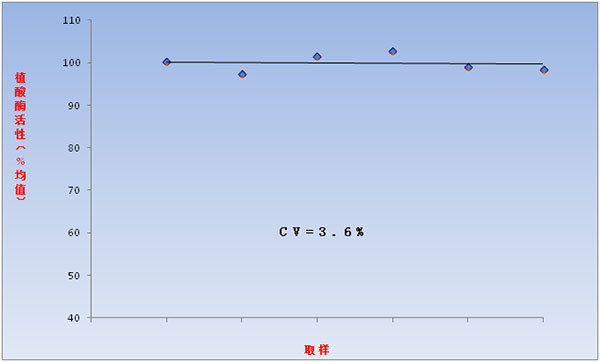

Mixing uniformity of Aobo phytase in laying hen feed

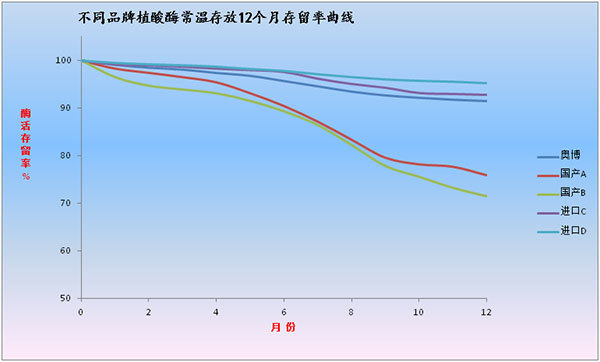

♦ High stability

1. Fermentation process: fully automatic liquid submerged fermentation based on cell physiology and engineering information processing;

2. Post-treatment: Unique post-treatment production process improves the stability of phytase;

3. ISO9001 and ISO22000 certification system to ensure the stability of product batches.

4. Special stabilizers and protective agents are added in the post-processing process to ensure that the enzyme activity is stable and the loss rate is extremely low when the product is stored at room temperature.

♦ Strong adaptability

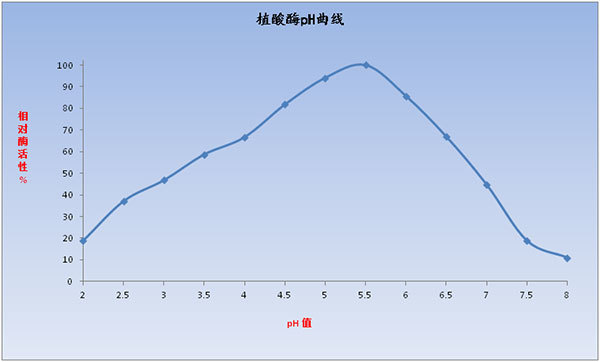

5. The pH range of action is wide, and it has high enzymatic activity in the range of pH 2.5-pH 6.5.

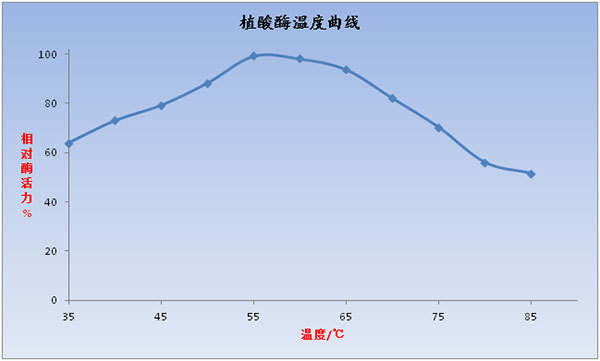

6. The optimum temperature is close to the physiological conditions of animals.

Product dosage form and characteristics

♦ Powder dosage form: It is a temperature-resistant strain which is directly spray-dried from fermentation broth, so it has a certain temperature-resistant performance and is suitable for various livestock and poultry powder feeds.

♦ Micro-granule formulation: Micro-granules have good fluidity and solubility, overcome the shortcomings of dust and electrostatic adsorption during the use of powder products, and are used in feed with good mixing uniformity, which is more suitable for powder feed and granulation temperature. Use in pelleted feeds not exceeding 80°C.

♦ Liquid dosage form: suitable for post-spray addition of pellet feed, so that phytase completely avoids the damaging effect of high temperature on it.

► The liquid phytase developed by advanced post-fermentation treatment technology has the characteristics of high specific activity, high purity and high clarity;

► The enzyme protein molecule modification technology is applied, and special stabilizers are added to ensure the stability of the enzyme preparation in liquid state. Store in cold room (0-4℃), up to 1 year; store at room temperature, up to 6 months.

|

Other indicators of liquid phytase (take 50000U/g as an example) |

|

|

Phytase type |

3-Phytase |

|

Optimum temperature |

55℃ |

|

Optimum pH |

5.5 |

|

Degradation pathway from IP6 to IP1 |

3-4-5-6-1 or 3-4-6-5-1 |

|

Liquid Phytase pH |

4.0-6.0 |

|

Color |

Yellow brown, clear and transparent without impurities |

|

Kinematic viscosity |

12.0-12.5 m2/s |

|

density/specific gravity |

1.09-1.10 |

Product Specifications

♦ Powder: 5000U/g, 10000U/g, 20000U/g, 50000 U/g, 100000 U/g, 200000 U/g, etc., 25Kg paper-plastic composite bag.

♦ Micro particles: 5000U/g, 10000U/g, 20000U/g, 50000 U/g, 100000 U/g, 200000 U/g, etc., 25Kg paper-plastic composite bag.

♦ Liquid: 5000U/ml, 10000U/ml, 20000U/ml, 50000 U/g, 100000 U/g, etc., 25Kg or 200Kg sterile plastic bucket.

Instructions

Calculated at 20000U/g enzyme activity, the addition amount is as follows

|

Animals |

Recommended dosage |

Recommended alternative phosphorus source ratio (%) |

|

pig |

60-100g/t |

30-50 |

|

meat and poultry |

60-100g/t |

30-50 |

|

eggs |

50-60g/t |

50-70 |

Storage and Shelf Life

It should be stored in a cool, dark, ventilated and dry place, and avoid mixing with toxic, harmful or other polluting items.

Shelf life: 12 months for solid products and 6 months for liquid products.

MESSAGE

©2022 Aocter Group